Market Leader inMicro Molding

The Medical Device and Life Science markets are a constantly and rapidly changing landscape. As technology expands, so do the many possibilities for new, innovative medical devices and implants. That's why it's crucial to find a trusted contract manufacturing leader in the field of micro molding to collaborate with. Our experienced engineers are dedicated to providing our customers with the highest quality products and unparalleled service.

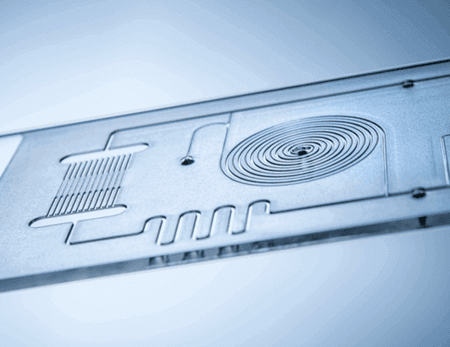

AdvancedMicrofluidics

More and more, the bioengineering and medical fields rely on microfluidic devices in order to properly conduct research and development. In the biopharmaceutical and genetic engineering industries, microfluidics are a crucial component, because they are efficient, reliable, and cost-effective. Therefore, it is essential that microfluidic devices are manufactured from the highest quality materials in a clean, certified setting. PDC offers just that.

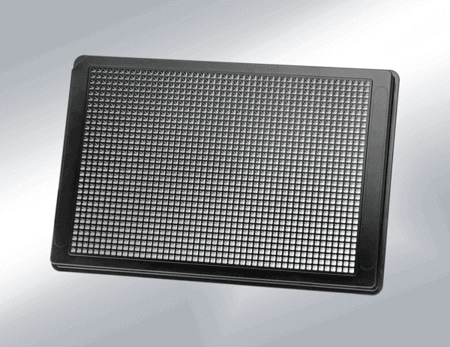

Custom DesignedMicroplates

PDC excels at providing customers in the healthcare and life science fields with the custom solid-and-film-bottom micro titer plates they need. We design for manufacturability, with in-house mold production and cleanroom production and assembly. And, we have the capabilities to work with both complex geometries and materials. When you work with PDC, you can count on us to produce the components you need, when you need them.

As pioneers in breakthrough technologies, PDC proudly manufactures components & products for the medical device and life sciences industries that consistently meet exceedingly high requirements.

We Offer Solutions For Your Industry

Within the medical sector, our capabilities support a range of segments within the industry.

The human heart is one of the body’s most vital organs. Modern medical science has made it possible to repair heart health issues using advanced technology, microcatheter devices & delivery systems capable of restoring proper organ function. At PDC, we offer manufacturers micro molding that enables them to create the cardiovascular medical devices needed to provide critical patient care.

A patient’s quality of life is dependent on their ability to live a pain-free, independent life. The ability to move freely is an important aspect of that, and orthopedics plays an important role. Technological advancements in the field of orthopedic device manufacturing have made it so surgeons are able to offer a broader scope of life-improving procedures. As an orthopedic device manufacturer, you need quality components from a trusted company. At PDC, we offer the micro molding capabilities that manufacturers need when producing these surgical devices.

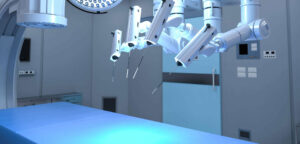

In recent years, many innovations have been made in the advanced surgical device field. As advanced surgical devices become more complex, it becomes increasingly necessary to develop micro molded components that are both high-quality and effective. At PDC, we offer the micro molding capabilities that manufacturers need when producing these surgical devices.

The field of ophthalmology is devoted to helping people maintain and improve their vision, often through surgical procedures. As technology improves, more advanced opthalmic surgical equipment and devices are being developed every day. The precise nature of this equipment and these devices calls for the highest quality micro molded components. As a manufacturer, you need a company you can trust to provide you with the components you need, to your exact specifications.

When people think about drug delivery systems, they often think about the needle and syringe used to deliver immunizations and medications. However, numerous types of drug delivery systems are used in the medical field. Solutions can include designing and manufacturing devices used to deliver drugs and biologics, such as pumps, injectors, and implantable devices.

When diagnosing an illness or disease, time is often of the essence. Point-of-care diagnostic devices help to obtain diagnostic results while the healthcare provider is with the patient or in a nearby laboratory setting. At PDC, we help those who manufacture point-of-care diagnostic devices to advance PCR and clinical chemistry testing.

The pharmaceutical research industry is constantly growing. Advanced pharmaceutical applications are helping to address health concerns ranging from autoimmune diseases to cancer. In order for effective research to take place, high-quality, advanced devices are required. At PDC, we help those who manufacture pharmaceutical research devices get the components they need.

The human heart is one of the body’s most vital organs. Modern medical science has made it possible to repair heart health issues using advanced technology and microscopic devices that are capable of restoring proper organ function. At PDC, we offer micro molding to manufacturers that enables them to create the cardiovascular medical devices needed to provide critical patient care.

When people think about drug delivery systems, they often think about the needle and syringe used to deliver immunizations and medications. However, there are numerous types of drug delivery systems used in the medical field, and as a drug delivery manufacturer, you know how crucial it is that the components you use in developing these devices is of the highest quality.

Many innovations have been made in the advanced surgical device field in recent years. As advanced surgical devices become more complex, it becomes increasingly necessary to create micro molded components that are both high-quality and effective. At PDC, we offer the micro molding capabilities that manufacturers need when producing these surgical devices.

The field of ophthalmology is devoted to helping people maintain and improve their vision, often through surgical procedures. As technology improves, more advanced opthalmic surgical equipment and devices are being developed every day. The precise nature of this equipment and these devices calls for the highest quality micro molded components. As a manufacturer, you need a company you can trust to provide you with the components you need, to your exact specifications.

A patient’s quality of life is dependent on their ability to live a pain-free, independent life. The ability to move freely is an important aspect of that, and orthopedics plays an important role. Technological advancements in the field of orthopedic device manufacturing have made it so surgeons are able to offer a broader scope of life-improving procedures. As an orthopedic device manufacturer, you need quality components from a trusted company. At PDC, we offer the micro molding capabilities that manufacturers need when producing these surgical devices.

When diagnosing an illness or disease, time is often of the essence. Point of care diagnostic devices help to obtain diagnostic results while the healthcare provider is with the patient or in a nearby laboratory setting.. At PDC, we help those who manufacture point of care diagnostic devices get the components they need.

The pharmaceutical research industry is constantly growing. Advanced pharmaceutical applications are helping to address health concerns ranging from autoimmune diseases to cancer. In order for effective research to take place, high-quality, advanced devices are required. At PDC, we help those who manufacture pharmaceutical research devices get the components they need.

We're Here for You, From Start to Finish

When you work with PDC, we’re with you from the beginning of your project to the end. So we are pleased to provide you with these quality products, made to your specifications:

1 Initial Contact

When you contact us with your project needs, our experts will touch base with you quickly.

2 Discovery

We'll then take the opportunity to learn more about your product requirements.

3 Design for Manufacture

We will follow the DFM principles to manufacture a product that meets your performance and quality standards.

4 Prototype

A preliminary model of your component & leveraging our in-house tool design.

5 Build & Develop

In this phase, any changes or updates to your prototype will be integrated into the final tooling and production.

6 Commercialization

In our advanced manufacturing facility, we will produce the component to the quantity you require.

Our Facility

PDC boasts a 20,000-square-foot integrated tooling and manufacturing facility dedicated to healthcare and life sciences. Our facility is process-focused for ease of internal communication, efficient operations, and material flow. We are an exclusively cleanroom production and assembly facility featuring first-rate equipment for greater control over quality and lead times. We are proudly certified to the latest ISO 13485:2016 standard. As a professional and experienced molding company, we are a competent and trustworthy partner, whether you’re a startup company or blue-chip manufacturer.